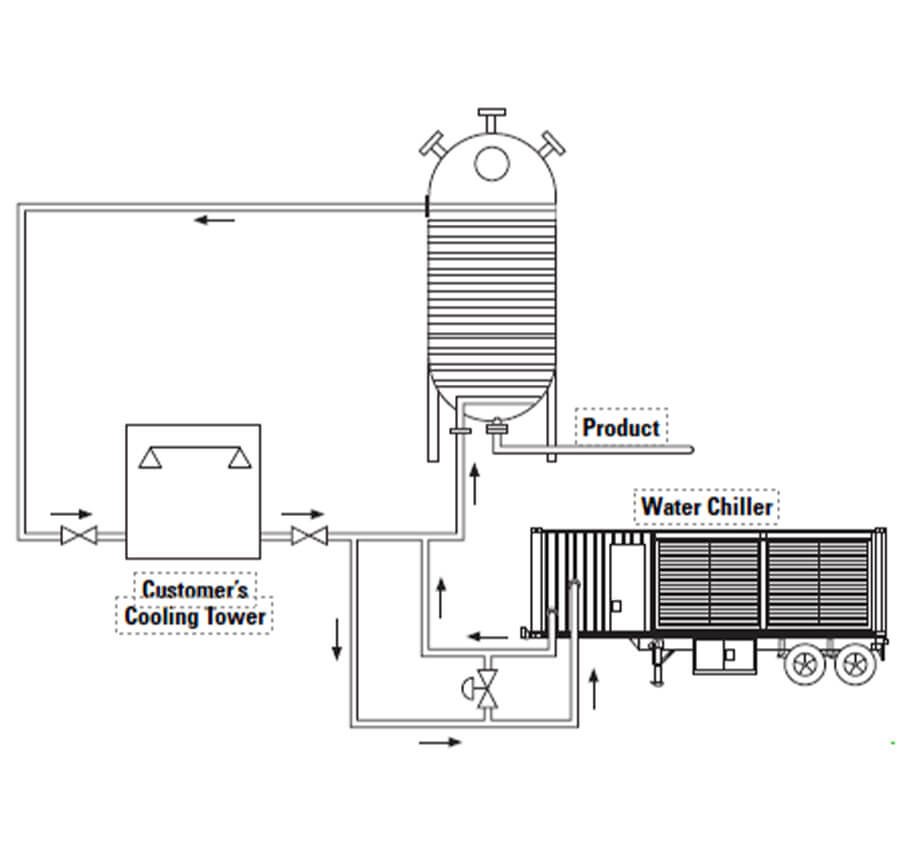

Product Storage

Many industries rely on cool room facilities (38° F to 40° F) for storage of perishable products. These facilities typically use chilled water or refrigeration equipment to produce the necessary cooling.

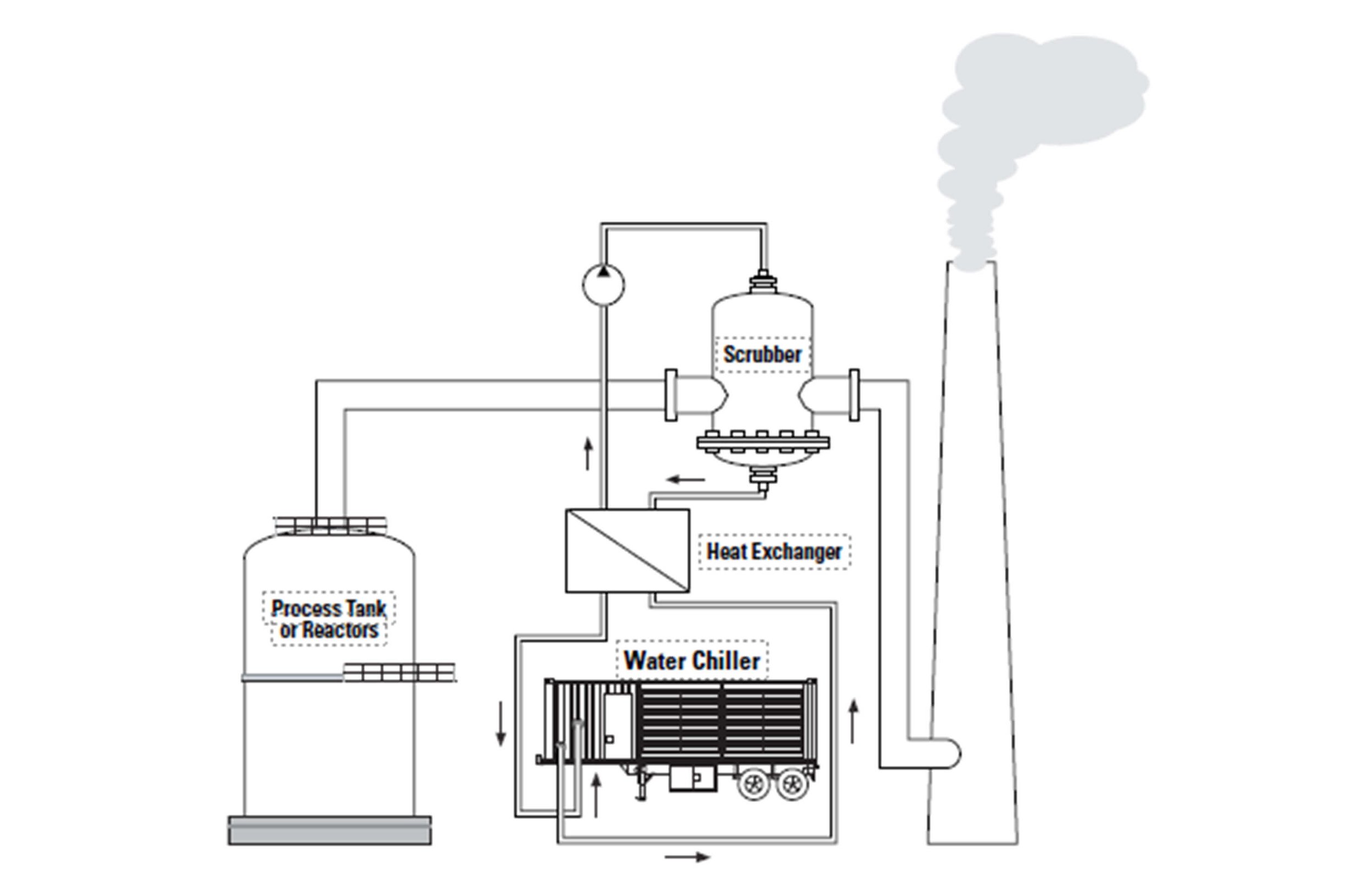

Scrubber Cooling

Scrubbers use a solution to remove chemicals from gases within a tank. A scrubber must be cooled to maintain low emission and high production levels.

Jacketed Reactor Cooling

Companies that produce chemicals or pharmaceuticals use reactors. Water or brine is usually circulated through the reactor jacket or coils to control the heat of the reaction. Without sufficient cooling, reactor operations might have to be shut down.

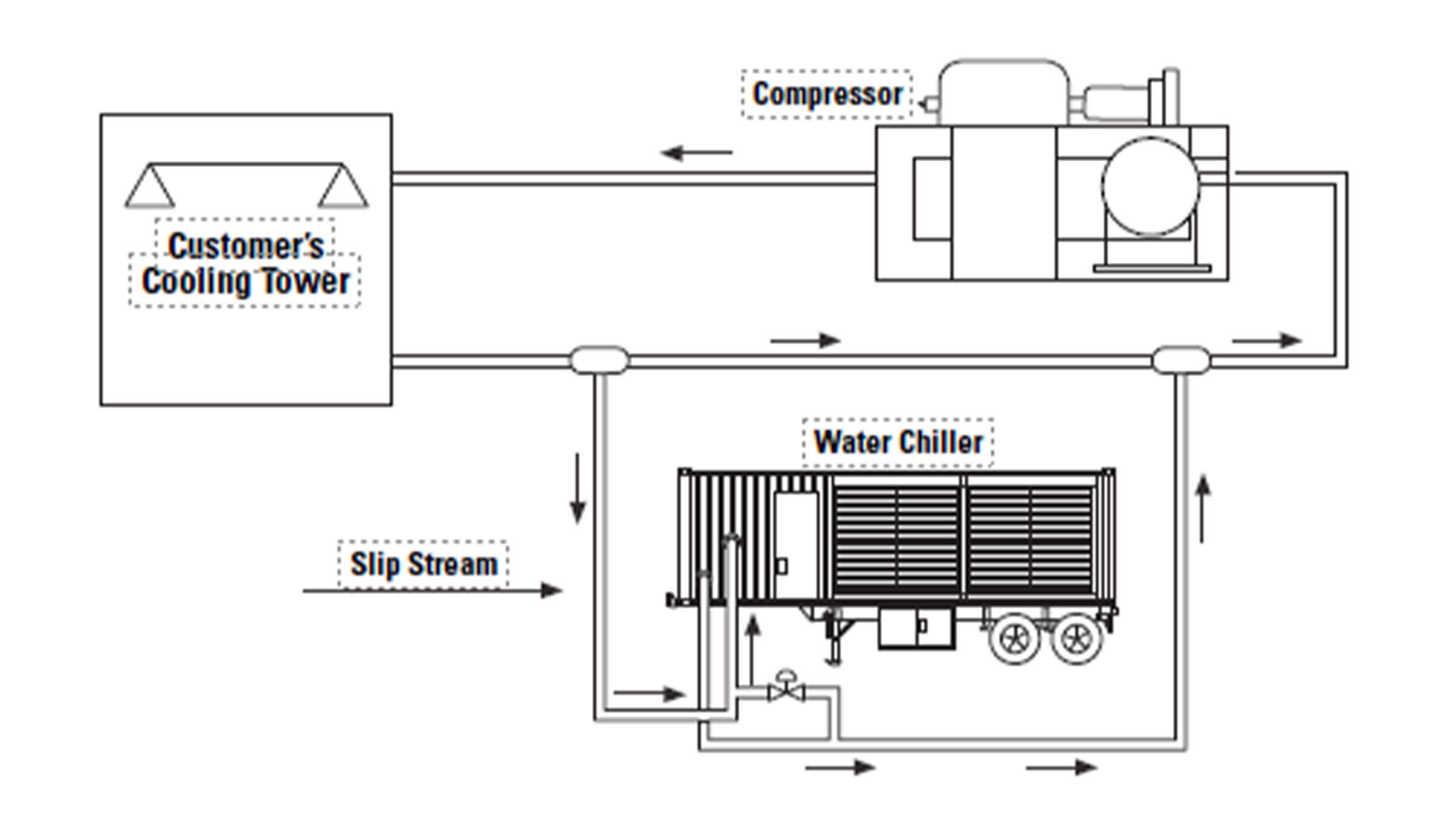

Wet Gas Compressor Cooling

Wet gas compressors compress light gases such as butane and propane and deliver them to a cat cracker as a portion of the feed to a reaction chamber. Many of these compressors are cooled using a water jacket and cooling tower water.

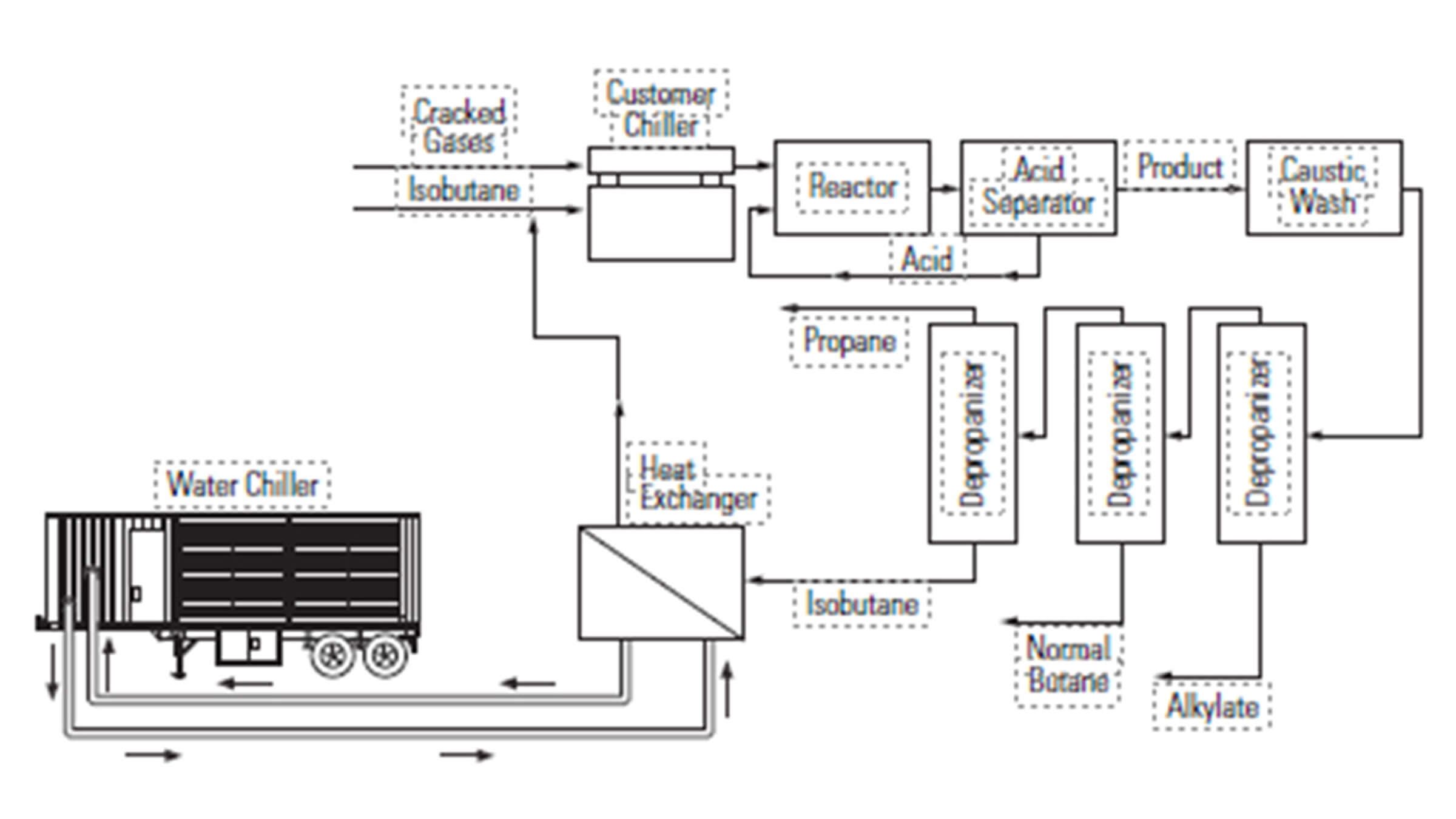

Alkylation (Alky) Cooling

Oil refineries employ chemical reaction processes to produce alkylate, a product that is blended with gasoline to increase its octane rating and lower its vapor pressure.

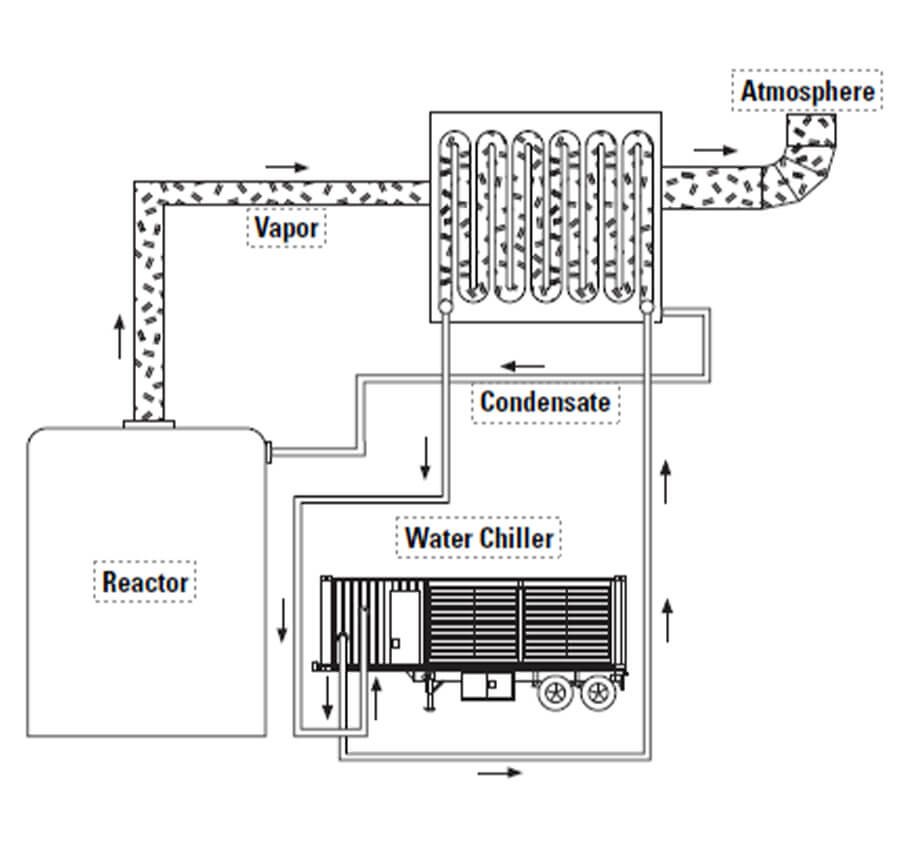

Condenser Cooling

During summer months, the existing cooling equipment is stressed and may not keep up with demand, requiring cutbacks in production. Rental chillers can provide both backup and supplemental cooling capacity. The drawing below shows one possible installation.

Waste Water Treatment

A widely used method of treating wastewater is through treatment ponds, where bacteria break down the waste materials. These microorganisms are heat sensitive and die if the pond gets too hot.

Ice Rink Cooling

Rental systems are always a first choice in the event of permanent equipment failure at ice rinks. Rental chillers are also ideal for temporary and seasonal rinks—which are becoming more common—as they do not require a large capital investment.

Concrete Cooling

Some concrete pours must maintain a precise temperature to achieve the specified strength and characteristics. In these cases, contractors often have to work at night, which increases their labor costs.

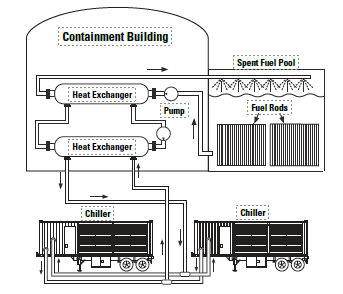

Containment & Spent Fuel Pool Cooling

Nuclear reactors use highly radioactive materials to produce great amounts of heat. These processes are housed in containment buildings that must have a constant supply of chilled water and air. The byproduct of the reactor is spent fuel that remains radioactive and must be constantly cooled in a pond or tank.

Vapor Recovery and Liquefied Gas Storage

Liquefied gasses such as butane, propane, natural gas and others are condensed and stored in large pressurized tanks. A portion of this liquefied gas boils off as vapor, both during production and storage and must be re-condensed and returned to the storage tank.

Supplemental Cooling Tower Water

Rental chillers are the ideal solution to supplement cooling tower capacity and lower water temperature sufficient to support production processes.