Product Storage

Many industries rely on cool room facilities (38° F to 40° F) for storage of perishable products. These facilities typically use chilled water or refrigeration equipment to produce the necessary cooling.

Plastics Production Processes

Many different processes within the plastics industry rely on a continual supply of chilled water.

Large Motor Cooling

Production processes are sometimes limited during summer months because of overheating of large motors, transformers, motor control centers and other equipment. This is particularly true when the equipment is located in a dirty or dusty environment.

Condenser Cooling

During summer months, the existing cooling equipment is stressed and may not keep up with demand, requiring cutbacks in production. Rental chillers can provide both backup and supplemental cooling capacity. The drawing below shows one possible installation.

Waste Water Treatment

A widely used method of treating wastewater is through treatment ponds, where bacteria break down the waste materials. These microorganisms are heat sensitive and die if the pond gets too hot.

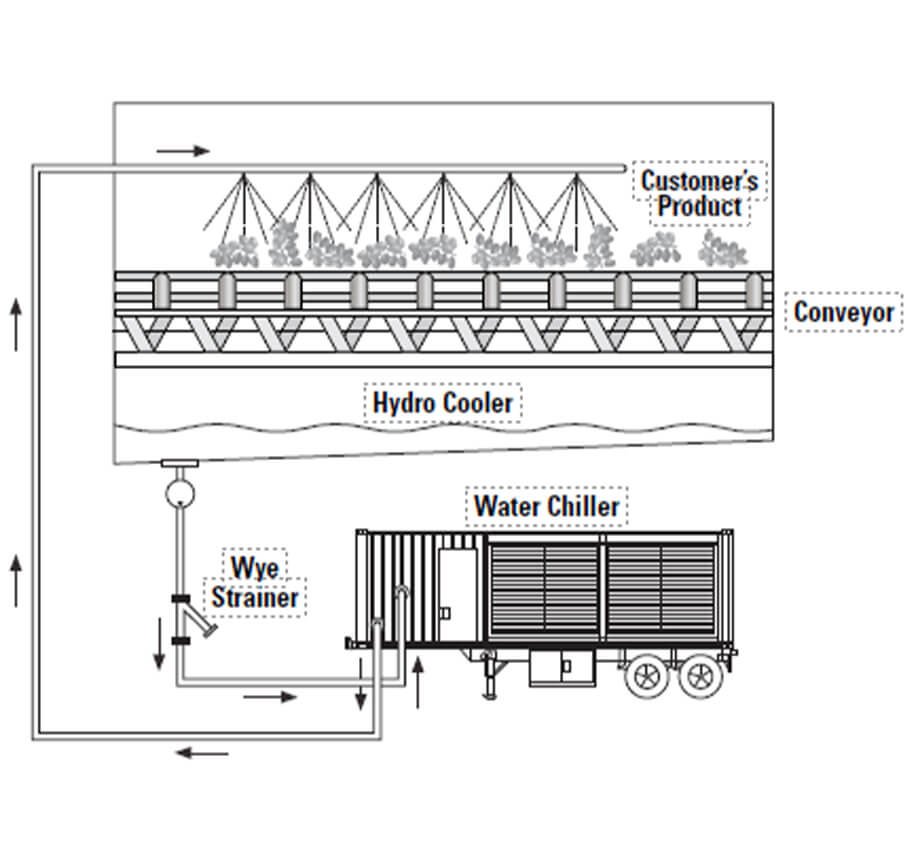

Food Products Cooling and Quenching

Because of the seasonal nature of harvesting, many companies may find it more economical to rent chillers, rather than owning permanent systems.

Concrete Cooling

Some concrete pours must maintain a precise temperature to achieve the specified strength and characteristics. In these cases, contractors often have to work at night, which increases their labor costs.

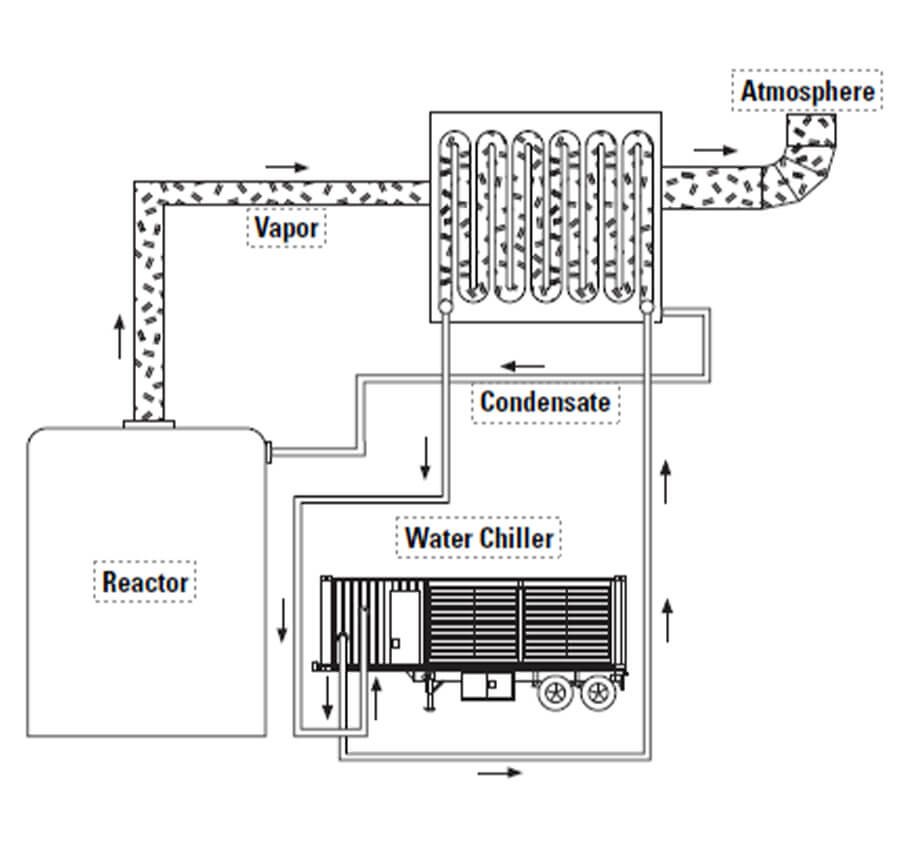

Vapor Recovery and Liquefied Gas Storage

Liquefied gasses such as butane, propane, natural gas and others are condensed and stored in large pressurized tanks. A portion of this liquefied gas boils off as vapor, both during production and storage and must be re-condensed and returned to the storage tank.

Supplemental Cooling Tower Water

Rental chillers are the ideal solution to supplement cooling tower capacity and lower water temperature sufficient to support production processes.